Related High Temp Blog Articles

SPIE Photonics West 2024

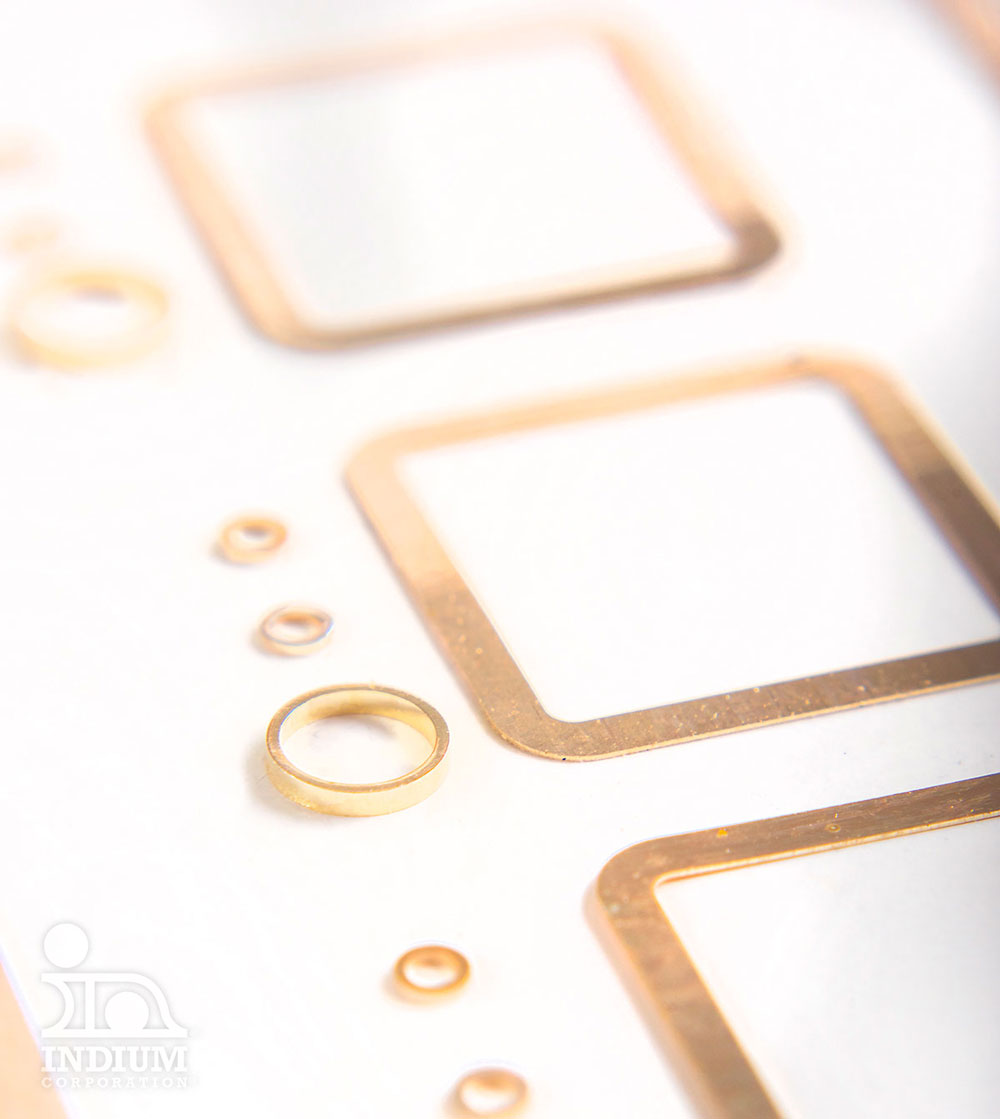

Indium Corporation® featured our Precision Au-Based Die-Attach Preforms at SPIE Photonics West 2024, the world’s premier event for lasers, biomedical optics and biophotonic technologies, quantum, and optoelectronics...

Read MoreWhich Off-Eutectic AuSn Alloy Do I Use?

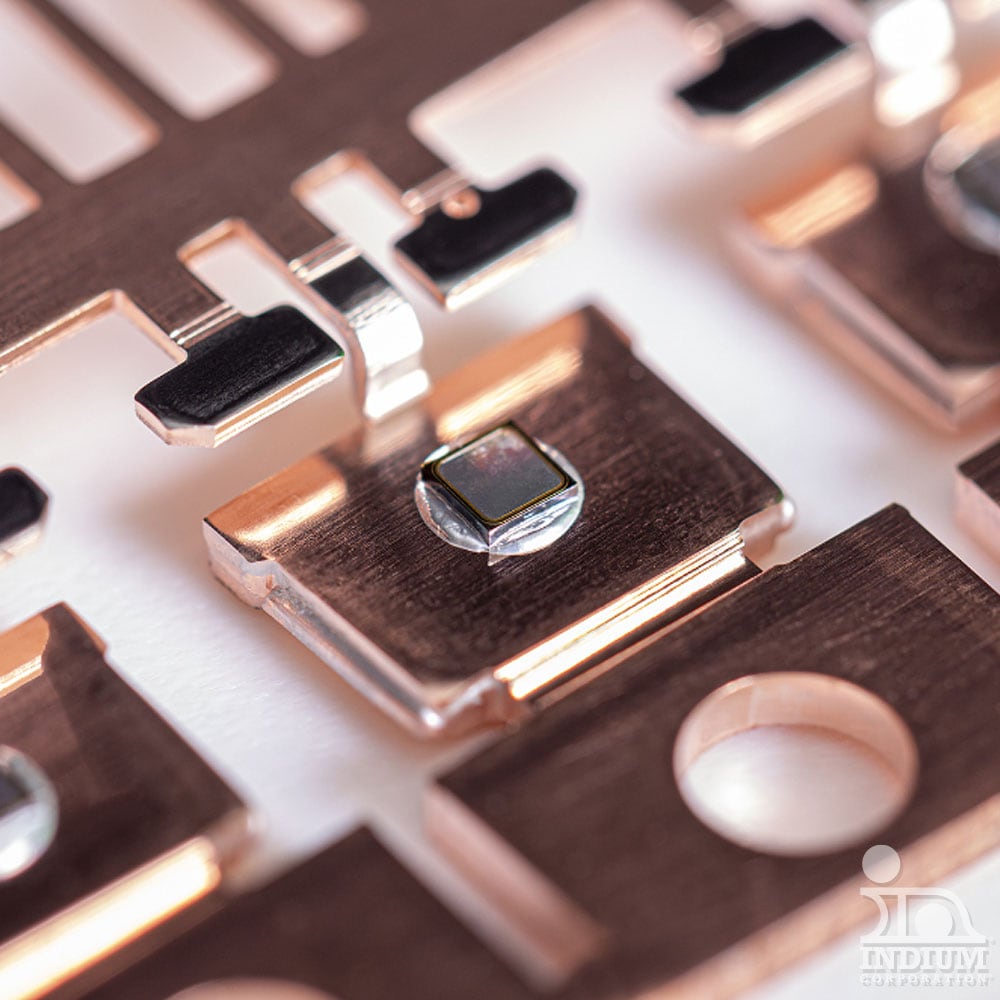

Plating dies and/or substrates with pure gold works well to prevent the components from oxidizing, but can lead to undesirable gold-rich solder joints. Using an off-eutectic AuSn alloy as the solder material accommodates for these thick gold metallizations, allowing for the exact adjustment of the final solder joint composition to guarantee strong solder joints in die-attach applications.

Read MoreIMS 2022!

The International Microwave Symposium (IMS) (June 21-23) is the premier annual international meeting for technologists involved in all aspects of microwave theory and practice. It consists of a full week of events, including technical paper presentations, workshops, and tutorials, as well as numerous social events and networking opportunities.

Read MoreWhen Life Gives You Lumens, Make LED Paste!

AuLTRA™ 3.2 and AuLTRA™ 5.1 are air or nitrogen reflow AuSn solder pastes specially formulated for higher processing temperatures and assembly needs required in high-power LED module array applications. These AuSn solder pastes offer consistent printing and reflow, in addition to exceptional wetting and low-voiding. AuLTRA™ 3.2 and AuLTRA™ 5.1 solder pastes are available in these alloy compositions: 80Au/20Sn, 79Au/21Sn, 78Au/22Sn, and 77Au/23Sn, and powder sizes 2 to 7SGS.

Read More‘Aye, you,’ do you make jewelry?

While continuing to be a premier solder materials manufacturer and supplier, Indium Corporation now manufactures and supplies jewelry making materials. These materials are available in 99.99% gold grain, and pink, purple, and red colored gold.

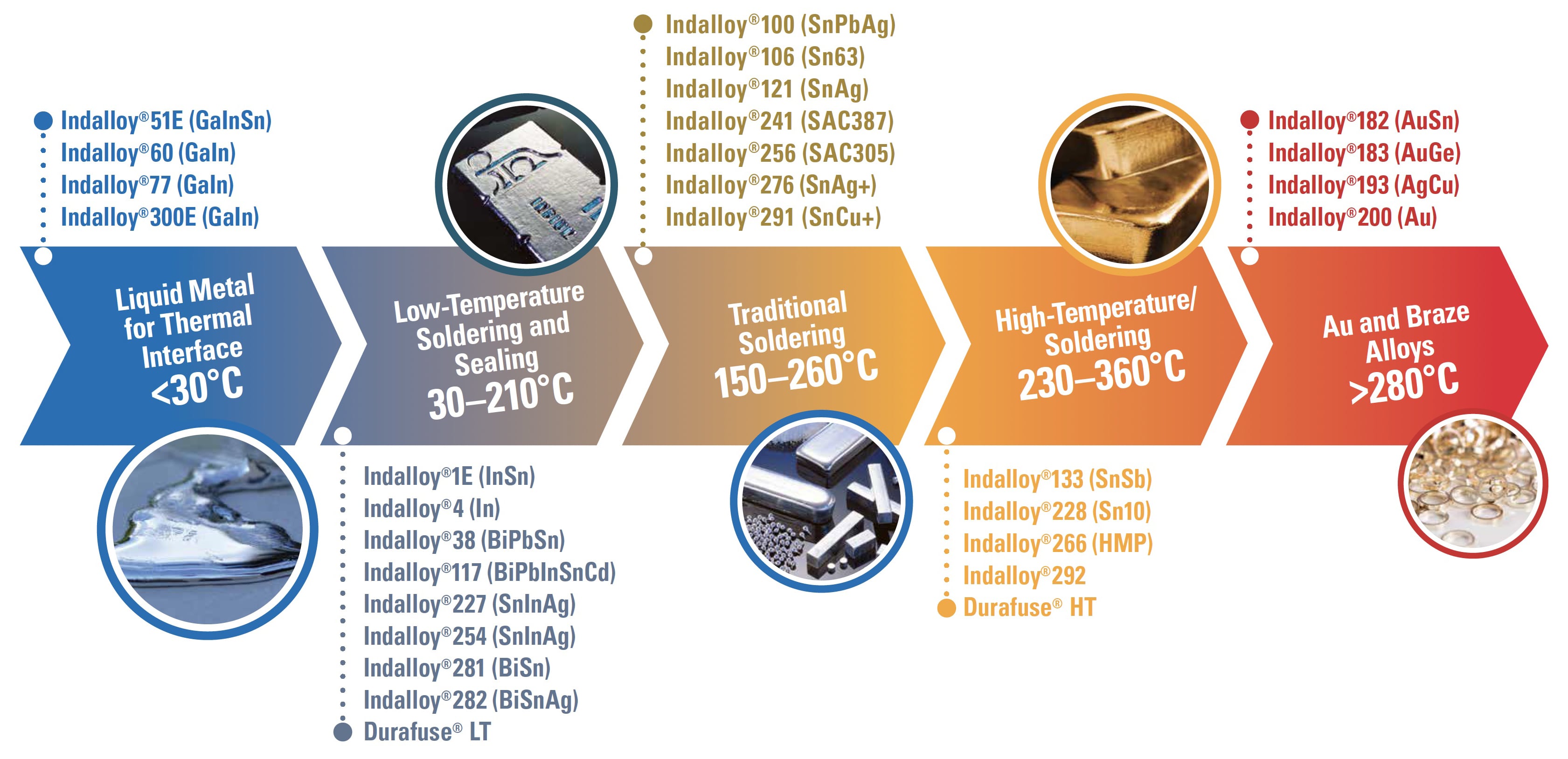

Read MoreIndium Corporation is a leading gold and silver alloy bonding and brazing materials innovator for high-temperature and high-reliability applications, such as die-attach and hermetic sealing, in various industries including automotive, RF infrastructure, military, laser, and aerospace.

With over 200 alloys available, we have alloy solutions for temperatures up to 1,100°C. Providing an alternative to traditional high-lead options, Indium Corporation currently offers and is continuously developing novel lead-free solutions such as gold solders, sintering, preforms, and alloy technology with new flux systems

High Temperature Products

Lead-free options from Indium Corporation

Gold Solders

Gold based alloys offer strong bond strength, excellent corrosion and oxidation resistance, and good thermal and electrical transfer at the braze joint.

Sintering Products

Indium Corporation’s QuickSinter® silver sintering pastes are high metal-loading materials designed to fit easily into a dispense process with no change of deposition equipment. The pastes can also use fast “reflow-like” (RFL) sintering processes to form strong joints on many standard leadframe, DBC, and IPM pad finishes, and will bond strongly to die with Ag, Au, or Cu surfaces.

Silver-Based High Temp Alloys

High thermal and electrical conductivity, capillaries very well into joints, and holds up well in applications with lots of stress and with CTE mismatches.

| Attributes | Alloys | Temperature | |

|---|---|---|---|

| Gold-Based Alloys | Strong bond strength, excellent corrosion and oxidation resistance, and good thermal and electrical transfer at the braze joint. | Indalloy®200 (100Au) Indalloy®178 (82Au/18In) (96.8Au3.2Si) Indalloy®183 (88Au/12Ge) Indalloy®270 (75Au/25Sn) Indalloy®269 (78Au/22Sn) Indalloy®271 (79Au/21Sn) Indalloy®182 (80Au/20Sn) |

1064°C Eutectic Solidus 451°C / Liquidus 485°C 363°C Eutectic 356°C Eutectic Solidus 278°C / Liquidus 332°C Solidus 278°C / Liquidus 301°C Solidus 278°C / Liquidus 289°C 280°C Eutectic |

| Silver-Based Alloys | High thermal and electrical conductivity, capillaries very well into joints, and holds up well in applications with lots of stress and with CTE mismatches. | Braze Indalloy®B962 (99.99Ag) Indalloy®193 (72Ag / 28Cu) |

962°C Eutectic 780°C Eutectic |

| Standard Materials | ||||||||

|---|---|---|---|---|---|---|---|---|

| Comments | Sn | Ag | Sb | Au | Bi | Ge | Solidus (°C) | Liquidus (°C) |

| Lower Tj IGBT usage | 96.5 | 3.5 | 221°C | Eutectic | ||||

| Also known as "J-alloy" | 65 | 25 | 10 | 233°C | Eutectic | |||

| Commonly used in step-soldering processes | 95 | 5 | 237°C | 240°C | ||||

| Highest Sb content possible in standard Sn/Sb wire | 91.5 | 8.5 | 241°C | 248°C | ||||

| Commonly used in step-soldering processes | 90 | 10 | 243°C | 257°C | ||||

| Highest melting standard Sn/Sb alloy | 86 | 14 | ||||||

| Very poor solder-ability | 11 | 89 | 262°C | 360°C | ||||

| Very high tensile strength and thermal / electrical conductivities | 20 | 80 | 280°C | Eutectic | ||||

| Usable for very high Tj die-attach such as SiC | 88 | 12 | 356°C | Eutectic | ||||